HOLIDAY MOUNTAIN, NY

Mike Taylor is two years into rebuilding Holiday Mountain, which faced closure when he purchased the property in May 2023. Last summer, he focused on immediate needs such as controlling erosion and making sure key lifts were safe to operate. This summer, Taylor turned his attention to upgrades. Holiday is installing a fixed-grip quad to replace a 1968 Poma double, significantly boosting snowmaking, adding lights, and cutting two new trails.

The lift is a used Borvig quad from Massanutten, Va., that has been completely overhauled. As of mid-July, Hagen Shulz of Partek Ski Lifts was rebuilding sheave assemblies and fabricating a new drive bullwheel at his shop, which is only 40 minutes away. The quad will feature new low voltage controls from Elevation Controls. The motor was rebuilt at a shop in Pennsylvania, and all the towers and terminal structures were sent off to be galvanized. By the end of July, Jason Blenis of Dolomite Ski Area Services had completed nearly all the lift’s 13 tower foundations and terminal footers.

The new quad will run up the side of the Turkey Trot trail; the old lift ran up the center. In addition to improving the ski experience, the new alignment allowed the old lift to remain in place through mid-summer, in case the project was delayed. Alongside the new Turkey Trot lift, Taylor is installing all-new Snow-Bright LED lights and 23 SMI tower-mounted fan guns.

Elsewhere on the hill, Taylor’s in-house crew cut a new expert trail to the south of existing terrain and added an intermediate infill trail that will also receive new snowmaking. In total, he expects to install about 6 miles of steel snowmaking pipe this offseason and add 100 new HKD stick guns. Holiday has an unlimited supply of water from a river running alongside the property and built a new pumphouse last fall. This summer, a fourth 450 hp pump with VFD from Ratnik was delivered, which will increase pumping capacity by 33 percent. Ratnik will also supply a second diesel air compressor and air chiller for the expanded snowmaking system.

Taylor plans to continue expanding and improving the mountain. He’s on the lookout for two additional used fixed-grip chairlifts to reactivate terrain that hasn’t opened in many years.

SKI SANTA FE, NM

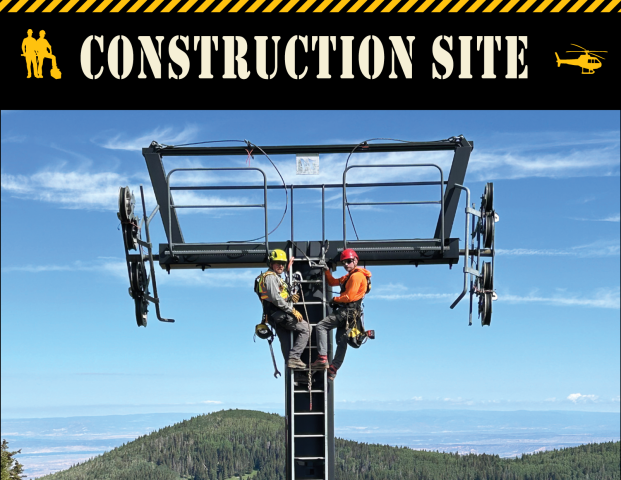

Ski Santa Fe is installing its first-ever detachable quad this summer, manufactured by Leitner-Poma of America. The new Santa Fe Express follows the path of a previous fixed-grip quad. When complete, the bottom drive, bottom tension machine will shorten what was a 12-minute lift ride to just over four minutes. A total of 72 carriers will cycle 2,000 skiers per hour. That is much improved from the previous lift, which ran about 400 fpm when not slowed or stopped for misloads.

The resort opted to install the lift itself instead of contracting with LPOA. “There are very few ski areas our size capable of self-installing a detachable lift, so this is something we are very proud of,” said Ben Abruzzo, Ski Santa Fe vice president and GM. In addition to cost savings, this model allows Ski Santa Fe to keep more winter staff employed year-round, and the crew will also get to know the lift and its systems as they assemble it.

With just 900 feet of vertical rise over a 4,000-foot lift line, the terrain is relatively mellow and accessible for a standard excavator. The team removed the outgoing lift’s chairs, haul rope, and upper return bullwheel in early May. The bottom drive terminal was carefully lifted by crane in mid-May and will be saved for use on another lift replacement project next summer.

By June, the team was busy fabricating wood and rebar forms for each of the lift’s 12 towers. A UH-60 Black Hawk helicopter provided air support in early July, removing old towers, pouring concrete for the new upper terminal, and delivering completed forms to pre-dug tower holes. The helicopter returned for a tower concrete fly day, with three different teams fanning out as the helicopter leapfrogged between them. By the end of the month, all tower and top terminal foundations were finished, the largest requiring nearly 70 yards of concrete. As of late July, Ski Santa Fe planned to set new towers in mid-August and begin setting both terminals via crane.

Abruzzo expects to have the new lift fully commissioned by early November.

GIANTS RIDGE, MN

Giants Ridge and SMI are halfway finished with a major snowmaking installation at the resort that includes 74 fully automated tower guns and 36,000 feet of new pipe. Ian Honey from SMI is overseeing a team of subcontractors including Lakehead Constructors and Parsons Electric. Most of the new guns will be Super Polecats, with 12 standard Polecats being installed in tighter areas. Each gun will be mounted on an SMI access tower.

Work began the third week of May, though weather has proved a challenge. In June, flood damage from a storm that dropped 6 inches of rain in less than six hours on the resort halted some work and closed the mountain’s summer operations. Drier weather will be key to finishing the project as scheduled by Nov. 1, said Giants Ridge director of facilities and mountain operations Sean Peyla.

With no on-hill air system, the project’s two main components are water infrastructure and electrical infrastructure. For the water infrastructure, Giants Ridge is installing epoxy-coated steel pipe, with some replacing old pipe and some expanding to trails that previously lacked snowmaking. New pipe will exit a mountaintop valve house at 8 inches and step down to 6 inches, 4 inches, and eventually to 3 inches at the bottom of the hill. Though no new pumps are included in the project, one of two supply pipes is being up-gauged from 8 inches to 10 inches. On the lower mountain, pipe is being buried in trenches. The pipe will remain above ground on the top third of the mountain, which is mostly granite cap.

On the electrical front, Giants Ridge is upgrading two electrical services on the bottom of the mountain to feed new circuits and existing circuits that are being replaced. About 39,000 feet of armored cable will be installed this summer to feed new HTM electrical pedestals for the fan guns.

As of mid-July, two trails had pipe and cable installed, with work progressing on multiple other trails. Once complete, 65 percent of Giants Ridge’s terrain will have automated snowmaking.

GORE MOUNTAIN, NY

Gore Mountain broke ground on its North Creek Ski Bowl enhancement project in March. The historic Ski Bowl was once its own mountain and was integrated into Gore in 2007. As part of the project, a new lodge is being built and a Leitner-Poma of America detachable quad is replacing a triple chair. Eventually, a first-in-the-U.S. hybrid zip-line coaster is planned to create a year-round activity hub.

The 18,300-square-foot lodge will house a food court, full-service restaurant, retail store, ticket office, day lockers, restrooms, and ski patrol, as well as two levels of outdoor patios. The steel frame building, built by contractor Bast Hatfield, will use structural insulated panels on the walls and roof for energy efficiency. All walkways and decks will be heated to reduce salt usage.

As of mid-July, lift components were arriving on site and LPOA crews had poured many of the concrete foundations. The original plan was to follow a new alignment, ending higher on the mountain and opening new terrain. “When we finally got the green light, construction costs had increased significantly, and the decision was made to keep the new lift in the same alignment to cut costs on the project,” said Gore GM Bone Bayse.

The bottom-drive detachable quad will span 3,534 feet with a 900-foot vertical rise compared with a 4,219-foot span and 1,001 feet of vertical in the initial design. Because of the planned summer operation, the lift will be capable of transporting 2,000 guests per hour with 100 percent downloading.

The lift is expected to be completed for the 2024-25 ski season, with the lodge to follow in September 2025. A completion timeline for the zip coaster is yet to be determined.

HATLEY POINTE, NC

Deb Hatley and her husband David acquired Wolf Ridge, N.C., in March 2023, aiming to do a cosmetic renovation and reopen for the 2023-24 season. By January 2024, they realized properly rebuilding the historic resort would require a one-year closure.

Hatley Pointe obtained its own general contractor license and hired full in-house creative and building teams. Teams gutted the 25,000-square-foot main lodge down to the studs, installing all-new electrical, plumbing, fire suppression, and HVAC systems. Every locker, dining, and retail area was renovated. The existing fireplaces were unsalvageable, so four gas- and one wood-burning fireplace were installed. The Hatleys kept as many original ceiling planks and wooden supports as possible.

Outside, the Hatleys paved the main access road, installed new wayfinding signage, landscaped with new terraces and removed overgrown vegetation. On the snowmaking front, nearly every existing pump and pipeline was failing. The team replaced 5,500 feet of damaged snowmaking pipe with new steel pipe. DemacLenko supplied 67 new Titan, Ventus, and Evo guns for fixed positions. The water storage pond was significantly expanded, and five new pumps were installed in a rebuilt pumphouse.

Much of this summer was focused on lifts, two of which had not operated in many years. A 2004 CTEC double received new lift houses, controls, and drive. For the other two lifts that had run more recently, an in-house team focused on rebuilding sheave assemblies and replacing grips as needed. The lodge, snowmaking, and lifts all required more work than the Hatleys initially planned for, but the ski area will reopen this winter with more than half of its 54-acre footprint expected to be open.

SUN PEAKS, BC

Sun Peaks Resort closed its West Bowl T-bar in late 2020 due to aging equipment. How to best reintroduce lift service to the high alpine bowl? The area settled on a 4,980-foot-long detachable quad from Doppelmayr that follows an all-new alignment, loading 400 feet lower on the mountain and unloading 80 feet higher.

Due to post-Covid bottlenecks, Doppelmayr’s earliest delivery slot was late 2024. To get ready, Sun Peaks began work almost immediately, as summer construction windows are short at 7,000 feet.

Permitting began in winter 2021-22, as the province of British Columbia required archaeological and wildlife assessments plus an environmental review. In summer 2022, Northwood Group of Kamloops and other local contractors completed site clearing and built new roads to both terminal locations. In summer 2023, contractors completed rough terminal grading and ran underground power and fiber to the top terminal. Newport Structures of Kamloops completed tower and terminal foundations. A Bell 214 helicopter delivered concrete along the hard-to-reach sections of the lift line.

In early April, a crew logged trail extensions in lower West Bowl over snow, minimizing environmental impacts. In May, Doppelmayr flew 16 towers into place with a Kaman K-Max helicopter. Final grading was completed once snow melted in June. As of July, six to eight Doppelmayr workers were erecting terminal steel for the 404 hp top drive, bottom tension lift. The upper terminal will have a covered parking rail for the lift’s 80 quad chairs.

Once complete, the $12 million project will rise 1,004 vertical feet in 5.5 minutes to serve relatively mellow trails and glades. Initial capacity will be 1,800 pph but can go to 2,400 pph if needed. Sun Peaks expects to have West Bowl ready for opening day in late November.

SUGARBUSH, VT

Sugarbush is replacing the 40-year-old mid-mountain Heaven’s Gate triple with a new Doppelmayr fixed-grip quad. Removal of the old lift began April 1 (Sugarbush closed May 5). The early start was needed to complete all blasting and initial excavation for the top terminal, upper towers, and trail regrading by May 15, when all such loud and disruptive activities must cease until Aug. 1 for the nesting and breeding season of the rare Bicknell’s thrush, which only nests in higher elevation forests of the Northeast. The project closed popular terrain a few weeks early, but that was essential for installation to be completed ahead of the 2024-25 season.

Snowcats and sleds were used to move the summit patrol shack, lift shacks, top towers, return bullwheel, and the haul rope down to the base area over snow, and to transport machinery to the summit and along the lift line. The snow road was maintained into the spring to ease transport and minimize earth disturbance. Doppelmayr and G.W. Tatro did the removal, and Sugarbush provided transport to the base area.

Blasting was done for the top roadway leading to the lift, top terminal mast foundation, the foundations for the top three new towers, and new tower 8 foundation. A large bulldozer was used to anchor a winch so an excavator could be safely lowered down to dig some of the new tower foundations.

The 261 hp bottom drive, bottom tension lift will rise 1,427 vertical feet in a span of just 3,562 feet. Fourteen towers will carry 120 carriers, which will travel at 485 fpm, sending 1,800 pph up the hill—faster than the old lift thanks to a Chairkit loading conveyor, but with similar capacity due to fewer carriers. The bottom terminal is moving 50 feet further uphill, and the area will be regraded to allow more room for the lift maze. The upper terminal location was regraded to ease maintenance, and the unload area was raised to minimize the uphill climb to access a couple of popular trails.

A helicopter was scheduled to fly concrete in and the remaining old towers out in mid-August, and new towers were to be flown in mid-September. The project is scheduled to be complete Oct. 27.

On neighboring Mt. Ellen, Sugarbush is nearing completion of a multi-year snowmaking upgrade that includes replacing 17 miles of pipe, installing new HKD Impulse guns and HKD KLiK hydrants (and doubling the number of hydrants on three trails), new VFDs on three midstation pumps, and new base station pumps. The upgrades give Mt. Ellen 1,800 gpm capacity and increased pressure from 130 psi to 400 psi to the 4,000-foot summit