SKI SUNDOWN, CT

Ski Sundown began construction of its first new chairlift in 37 years in mid-April. Owner Bob Switzgable chose a fixed-grip quad from Skytrac to replace a base-to-summit Borvig triple.

An in-house crew started removing chairs and spooling the haul rope from the vintage machine soon after skiing concluded this spring. Old towers had been set directly into concrete, so they were cut down with a torch. Sections of the lift were lifted into dumpsters for recycling, while chairs were auctioned to the public in May.

Skytrac sent construction leader Tim Nikou to guide Sundown’s team through the installation. As of late May, excavation for the new 2,000-foot-long lift was scheduled to begin June 3. A main power feed ran directly under the old lift’s bottom terminal, and it was relocated before construction on the new lift started. Sundown also hired a logging company with a skidder to widen the alignment for the quad.

The bottom terminal of the quad will include a loading conveyor, the pit for which requires significant depth. After the bottom terminal is excavated, crews will dig 10 tower foundations and the top terminal pad. Topography along the 558-vertical-foot span allows cement trucks to reach most footing locations; an excavator with a concrete bucket can reach the others. A helicopter will fly towers later in the summer if one is available; if not, plan B calls for a D8 bulldozer with custom trailer to haul them.

In addition to the obvious increase in capacity, the new lift will run seven days a week and improve mountain access. Previously, Sundown swapped back and forth between two lifts, one of which offered poor access to some trails.

Weekday and night skiers in particular will benefit from the new ride. Both terminals will feature LED lighting, and beginners should have an easier time loading with the conveyor. Connecticut typically experiences several thaws each winter, and the modern terminals can more easily accommodate snow cats thanks to higher clearances and no counterweight. The project is scheduled to be completed Dec. 10, ahead of Ski Sundown’s traditional mid-December opening.

LAKE LOUISE, AB

Doppelmayr Canada and Lake Louise are working to build a new six-seat bubble chair, the middle link of a three-lift route from base to summit, constructed over three years. Due to unique regulations in Banff National Park (more about that to follow), Lake Louise cleared the lift line, brought in utilities, and prepared the site starting last fall. Work resumed early this spring, over the snow, with Lake Louise personnel completing bolt cages and tower foundations with the help of a walking excavator. Concrete for the tower foundations was flown in by helicopter in mid-April.

Doppelmayr arrived on site in March and installed both terminals, using excavators and a tracked crane while the ski area remained open. Work areas were roped off; daily deliveries were completed before lifts opened and after lifts closed. The install included the top drive platform and its 1,073 hp AC motor, transported to the summit via snowcat and trailer. By the time the resort closed on May 5, both the top and bottom terminals were complete.

At one point in the spring, several grizzly bears emerged, and Lake Louise took care to move closures daily to keep both lift construction staff and skiers safe. Work then paused again for the peak summer months, when bears and lynx enjoy exclusive access to the front side of the mountain. Per Parks Canada, the mountain must remain closed to all construction and recreational access, with public areas surrounded by electric fences.

Once the summer closure concludes, Doppelmayr will return to set the lift’s 19 towers, pull the haul rope, and commission the lift. The 6,276-foot-long machine with a vertical rise of 2,087 feet will ultimately include 73 bubble chairs. Lake Louise plans to construct a carrier parking garage and is responsible for building the operator control shacks at each station.

The lift will add 2,000 hourly seats and, in combination with the first leg of the three-lift route to the summit, bring Lake Louise close to 7,000 pph from the base to summit on three different routes

SUMMIT AT SNOQUALMIE, WA

The Summit at Snoqualmie and a number of contractors are working to complete two fixed-grip chairlifts in different areas of the resort separated by Interstate 90. The more challenging of the two is at Alpental, where a new Doppelmayr triple will open newly-accessed terrain for the 2024-25 season. Snoqualmie began planning this expansion back in 2021, collaborating with the Forest Service, Eastside Consultants, and Re-Align Environmental.

Due to extremely challenging access at Alpental, with rugged terrain and no road to the sites of either station, construction of the new International triple has been a two-year project. A Doppelmayr construction manager along with the Snoqualmie team blasted rock and poured all the lift’s concrete from spring through fall 2023. For access, workers had to ride two existing chairlifts and then hike to reach the tower and terminal locations along the 3,800-foot alignment.

Work resumed over the snow in March, when snowcats hauled the largest pieces of the lift, including the haul rope, operator houses, and drive platform, up to the mid-mountain lower terminal site. This was no small task: Three winch cats pulled a fourth cat, itself hauling a custom-fabricated sled, with another cat pushing from behind.

Once Alpental closed for skiing in mid-April, three winch cats hauled a 75-ton tracked crawler crane to the drive terminal location to begin assembly. In midsummer, once snow melts off the tower foundations, a helicopter will fly the lift’s 13 lift towers and the top terminal into place. By December, skiers should be enjoying 1,345 vertical feet of steep, gladed terrain via the new lift. Because it will cater mostly to experts, the 345 hp chairlift will travel up to 500 feet per minute.

Snoqualmie originally planned to replace an existing Riblet to the Alpental summit as well, but that lift proved essential to access the site for the new International lift. So, the resort worked with Doppelmayr to instead install a new Alpenstar-model, bottom-drive quad chair at Summit West to replace one of the resort’s least reliable lifts, the Wildside. The new 2,073-foot-long machine will rise 652 vertical feet powered by a 180 hp conventional drive and will feature a loading conveyor and LED night lighting.

Workers cut and removed eight of the old lift’s towers, leaving five to serve as night lighting poles (the new lift follows a different alignment). Next for this project will be concrete, most of which can be poured via truck and the rest by helicopter. With the International and Wildside lifts completed, the resort will return to the planned Alpental summit lift replacement project in 2025.

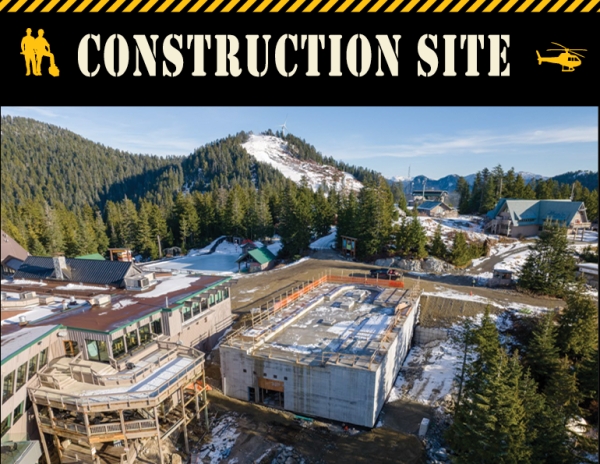

GROUSE MOUNTAIN, BC

Grouse Mountain is also completing a multi-year lift build this summer. Similar to Snoqualmie, the alignment is steep and remote, requiring special techniques and considerations. Grouse is one of only two ski areas in North America inaccessible by public road. Instead, guests board one of two aerial tramways to access the Vancouver ski area. Approaching 60 years old and with limited capacity, the older of the two tramways is being replaced with a Leitner-Poma eight-passenger gondola.

The new gondola will carry 1,000 guests per hour, nearly doubling capacity. The 1,200 hp lift will rise an impressive 2,800 vertical feet in just 5.5 minutes. Leitner-Poma designed the gondola with longer than normal hanger arms to achieve necessary swing clearance on the steep mountainside.

Unlike a chairlift, this gondola installation requires large concrete plazas at both terminals. North Construction and Hard Rock Construction served as contractors for the two station buildings and broke ground on Sept. 9, 2022. Due to the amount of concrete required, Grouse set up gravel and sand storage near the top terminal as well as a temporary concrete mixing plant. Plateau station concrete was poured on two levels. Two elevators were installed to eventually carry the lift’s 27 cabins from the return terminal to the storage facility below (the lower level can accommodate up to 41 cabins if future needs warrant them). The bottom terminal will house the lift’s drive systems, offices, a store room, and freight loading bay.

A helicopter was used to log the alignment. It crosses the newer of the existing aerial trams, which will remain in service. Construction managers worked carefully to avoid tram closures during installation and only subject guests to short delays.

The largest tower location required significant blasting and measures 75 cubic meters. Leitner-Poma began erecting terminal steel in May, completing the bottom terminal first. Nine of 14 towers will be flown in while four will be placed using a crane. The final tower will be winched to an aerial tram cabin, carefully carried up the mountain, and lowered into place. The project is expected to be complete by December, after which the historic blue tramway will be decommissioned.

MONT CASCADES, QC

Sometimes major capital projects are planned years in advance, others arise quickly out of necessity. The latter applied at Mont Cascades after the main lodge burned to the ground on Aug. 1, 2021. No one was injured, but the building housing rentals, a cafeteria, and washrooms was a total loss. Planning for a new lodge began soon after, while key functions were stood up in six temporary modular buildings.

The new 15,000-square-foot facility, designed by Rossmann Architecture, will serve both winter guests and a summer waterpark operation. The building is situated closer to the winter learning area than the old structure. The lower level is arrival-focused, housing rentals, guest services, washrooms, and a repair shop. The building nestles into the mountain slope, with a “walk out” effect on the main floor, where a grab-and-go cafeteria and dining area offer views of the hill.

Beaudoin Canada served as general contractor, and construction began in March 2023. A substantial amount of excavation was required to replace poor soil and construct the new foundation into the hillside. The prefabricated steel structure uses a combination of painted wood, stained wood, and steel cladding elements. All interior wood was sourced locally and is Forest Stewardship Council certified. Interior and exterior LED light fixtures maximize energy efficiency. Great attention was paid to the surrounding site, honoring setbacks for surrounding wetlands and forests.

The team ran into a number of challenges during construction, including design team changes, unexpected site conditions during excavation, and material cost increases. Completion was originally planned for spring 2024 but is now scheduled for fall, when the facility will provide an improved experience to guests and employees alike.

PANORAMA, BC

Panorama’s major spring projects aim to enhance the resort’s summer offerings. Ownership ordered a new SunKid monorail-style mountain coaster last fall, which was delivered to British Columbia via containers in mid-March. The new coaster is being installed in an area near a beginner chairlift where significant snow removal—20 feet in places—was needed as soon as the resort closed on April 14.

The coaster was designed to minimize environmental impact; installation required removal of just two hazard trees and next to zero grading. Panorama used a mini excavator to dig holes approximately every 3 meters along the track, which were filled with crushed gravel and then a steel pin and plate. Many of the track’s modular aluminum sections could be moved by hand for assembly. Eight Panorama lift operators and two SunKid employees from Austria worked on the installation, which was expected to take about six weeks.

In lieu of an uplift system, the coaster’s 45 sleds will be hauled up to the starting point via carrying brackets installed by the lift maintenance team on every other chair on the nearby chairlift. The crew also built a removeable wooden deck at the upper terminal for summer unloading. The only concrete pour required for the 1.2 km (3,937-foot) coaster was at the bottom, where guests step off sleds and lift operators attach the sleds to the chairlift for the return trip.

Panorama also purchased a lightly-used aerial adventure course from elsewhere in B.C., to add to its summer offerings. The steel structure, manufactured by EcoTrek, required the pouring of six concrete pillars in a star shape. Panorama hired a local excavating company to assist with the project, and the ropes course was being installed by its original manufacturer. As of late May, both the mountain coaster and adventure course were on a tight timeline to open by the Canada Day long weekend in early July.