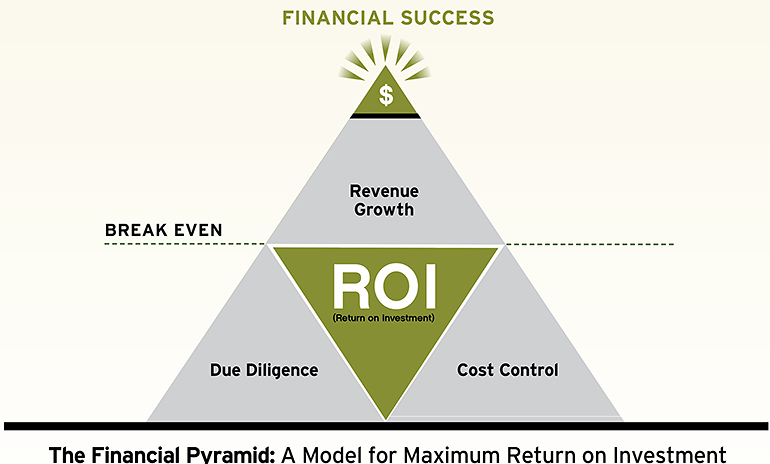

A strong and stable financial foundation is essential for a new building or major renovation project, particularly if you expect a reasonable return on investment. To get started, answer three questions: (1) Have we truly done our due diligence? (2) Do we have a strategy in place to challenge high costs through a combination of best practices and creative innovation? And (3), Can we maximize revenues to the degree necessary to overcome high construction and operation costs?

These fundamental considerations are illustrated in the “Financial Pyramid” at right. Loosely based on the pyramid found on the backside of the dollar bill, the pyramid denotes stability and points toward financial success (the dollar sign replacing the greenback’s Eye of Providence). The pyramid’s left side is built upon effective planning or due diligence—a foundational construction phase that incorporates research, programming, planning, and preliminary budgeting. The pyramid’s right side is about managing costs.

Given the financial risks involved in new construction, operators can no longer assume a “build it and they will come” mentality. As construction costs rise, capital investments must generate revenue like never before to earn a reasonable return. And that requires a thoughtful plan.

RESEARCH, PLAN, BENCHMARK, AND THEN GET CREATIVE

Rigorous due diligence helps build a solid project foundation. This idea is illustrated by Aspen Skiing Company (ASC), which—despite its prominence and financial success within the industry—takes no chances when it comes to new facilities.

“The value of early-stage planning and programming cannot be overestimated when developing these capital-intensive projects,” says ASC senior project manager Dana Dalla Betta. She notes that adverse financial impacts can reverberate through the operation for 20 to 30 years. “If we aren’t considering all factors early and we move forward too quickly without input from local jurisdictions or the contractor market, we may find ourselves in redesign, which is costly in terms of both time and money.”

A MULTI-STEP PROCESS

ASC’s process begins with an in-depth analysis of comfortable carrying capacity. That includes understanding volume and visitor demographics at different points on the mountain. ASC benchmarks its facilities to other successful projects both in and outside the mountain resort industry. Building flow and key features are analyzed; trends are identified and dissected.

Maximizing value. Next, the team considers unique branding for the prospective facility that complements the mountain while also differentiating the facility from others on property. ASC insists that each facility should have a purpose and a unique character, particularly on the food service front, so that guests can choose between the company’s four mountains and different venues to customize and vary their experience.

“Our facilities need to align with our brand in quality and consistency across the resort,” says Chris Kiley, senior vice president of planning and development. At the same time, they need “to be rooted to place,” he says. When starting a project, ASC focuses on “the specific attributes of the site as well as on the needs of the guests we will be serving—and with four mountains and a wide variety of natural terrain, these dynamics can really vary from location to location.”

This is why Sam’s, at Snowmass Ski Area, delivers a relaxed, high-end experience while Aspen Highlands’ Cloud Nine has a frothy vibe. Both venues have become destinations within the greater destination.

BUILDING THE BUILDING PLAN

The process doesn’t stop at capacity and branding. Based on its research, ASC’s facilities team develops a detailed building program that acknowledges industry standards and current best practices such as area metrics and efficiency standards. Then, they challenge themselves and their consultants to invent and think freely. How can we use technology to minimize square footage and streamline operations? What lessons did we learn from the pandemic related to outdoor dining? Could yesterday’s 26,000-square-foot building become 22,000 square feet today?

With building costs in many resort areas at well over $1,000 per square foot, a 15 percent reduction in building area pushes construction costs back, if not to pre-pandemic levels, then at least in the right direction.

The objective, though, is not to cut space for the sake of cutting, particularly if reductions impact quality, guest service, and a resort’s core values. The goal is to promote an exceptional guest experience at a cost that makes financial sense.

Sustainable building. For Aspen One—the parent company of Aspen Skiing Company, plus the hospitality and retail divisions—25 years of industry leadership in sustainable practices is a core value. Auden Schendler, Aspen One SVP of sustainability, notes that “this ethos heavily influences our approach to building projects, but in a practical, repeatable way.

“We’re not trying to build the best building on the planet, which is unattainable by anyone. We’re trying to do something that is highly replicable, within a tolerable budget, and understandable to the masses. The metric of success is: If every building in the world were built this way, would it represent a climate fix in the built environment?” Aspen One builds for the future while building smart.

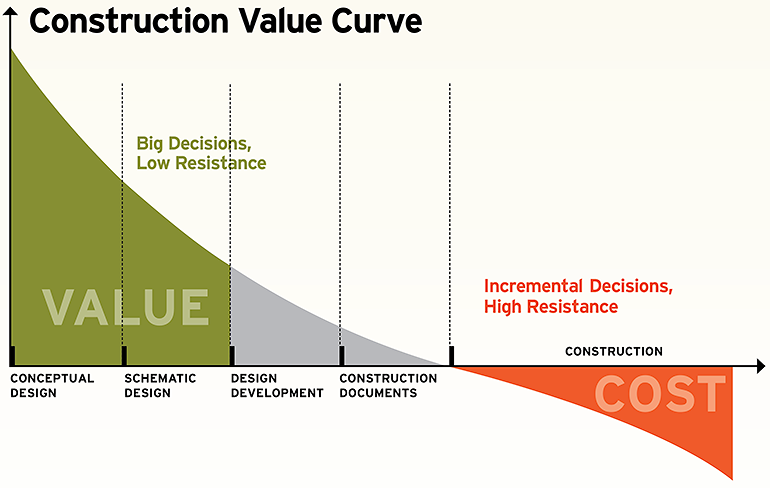

THE CONSTRUCTION VALUE CURVE

The importance of good, early decision-making is illustrated in the “Construction Value Curve” (below left). This graphic illustrates at what phase in a project real money can be saved, given the lack of vested interests and minimal resistance to making changes.

A stitch in time ... In the early concept and schematics design phases, in particular, there are opportunities to test assumptions and obtain preliminary project pricing. This can be used to establish a workable budget. This is where big decisions are made, and big savings can be attained. It is better to align your expectations and budget early, rather than watch a fine bottle of champagne be replaced by 12 ounces of lite beer.

All too often, however, projects are “value engineered” late in the game, when it is difficult to change course due to nearly complete design and engineering documentation and the time requirements associated with redesign. Quality documentation takes time, experience, and coordination between the project’s sub-consultant team. (Remember, time is money.) Excessive change orders at later stages can torpedo the budget. Even when savings can still be found in construction, the owner is likely to get 50 cents on the dollar.

CHOOSE YOUR TEAM WISELY

Weather, site accessibility, a well-considered construction schedule, and project sequencing can mean the difference between a project’s success and failure. Start in the spring, enclose a building before the snow flies, and consider, up front, any revenue impacts or needs for temporary services.

Choose your design and construction team wisely and they can meaningfully contribute to a value-based project well beyond their fees and associated costs. Make your partnership decisions based on demonstrable experience. Confirm that candidates understand the project type and resort operations.

Topography and seasonal constraints are also a factor. Does your team have experience building in the mountains?

The project approach. To facilitate the balance between quality design, schedule, and budget, abandon the traditional “design, bid, build” approach. Instead, bring in a general contractor early to provide pre-construction services. Typically, the owner and architect will issue a request for proposal from three or more pre-qualified contractors, from which one is selected based on fees, project understanding, and overall experience.

This project approach provides advantages over the traditional bidding approach, in which selecting the “low bid” often translates into an avalanche of construction change orders. The project approach puts you, the design and engineering consultants, and the general contractor on the same team.

The contractor’s job is to provide real-time estimating, review the developing documents against an established budget, and advise where savings can be achieved through alternate products and resources. The owner can maintain competitive bidding at the subcontractor level, having already negotiated the general contractor’s fees, general conditions, and a commitment to an open and transparent bidding process.

A RACE AGAINST TIME

Other potential savings are achieved by bringing the contractor on board early. In addition to streamlining the design phase, the pre-construction process allows the team to make market-driven adjustments. This is accomplished by reviewing regularly updated cost estimates and, subsequently, incorporating value analysis into the project. As a hedge against inflation, the team should also identify and procure long-lead and big-ticket items early. Prices can be locked in on generators, elevators, and mechanical equipment. Buy now and save later.

This race against time and availability also applies to the subcontractor market.

Bid timing. Traditionally, mountain projects are bid in early January for construction to begin in early spring. But increasingly, booming resort communities are seeing a scarcity of skilled subcontractors capable of completing a commercially scaled project by fall. If they are available, their prices will likely follow the rule of supply and demand.

A new trend to address the shortage is to go out to bid in the fall, when contractors are looking to line up work for the following year. In fall, there is likely more interest, more competition, and a better chance for fair pricing. The fall timetable also provides the contractor and the design team a reasonable timeline to assess contractor input, including cost saving substitutions and alternatives.

DO IT RIGHT THE FIRST TIME

Collective due diligence provides the fundamental first step toward a successful project. The formative, early design process is the time to maintain flexibility and make well informed decisions before they become costly redesign and construction changes. With strategic thinking and a budget in place, you can move into the design phase well poised to create something meaningful and, ultimately, profitable.

ASC’s Kiley summarizes this point: “If we are successful at creating a place that our guests seek out, and if we are also successful at collaborating with our operators to design a facility which operates efficiently and consistently, we will see that reflected in the bottom line, especially over time.” A portfolio providing differentiated and memorable offerings gives guests “a reason to visit again and again.”

THE NEXT STEP

Cost management represents the second fundamental component of any project. The trick is to achieve cost and quality objectives through efficiency and forward thinking. Simply cutting costs to hit a specific budget number often fails in the long term.

There is a saying in the construction industry: “While there never seems to be enough money do it right the first time, there always seems to be enough to do it the second time around.” In other words, future (more expensive) dollars are used to fix problems and deficiencies once they become too evident.

With this adage in mind, the next article in this series will focus on cost control while, at the same time, doing things right. “Saving, by Design” will focus on practices and technology that help mitigate high construction costs.

John Ashworth, AIA, is an architect and principal at Bull Stockwell Allen, a firm specializing in resort, recreation, and

hospitality design and planning.